In the dynamic world of manufacturing, the trend towards high-mix, low-volume (HMLV) production is gaining traction. This shift is driven by the need for increased customization and rapid adaptation to market changes. HMLV manufacturing, characterized by producing a wide variety of products in small quantities, is emerging as a crucial strategy for the future, particularly in industries like defense and aerospace.

The Rise of High-Mix Low-Volume Manufacturing

High-mix, low-volume manufacturing is becoming increasingly important as companies strive to meet the demands for personalized and customized products. This approach allows manufacturers to be more flexible and responsive to specific customer needs, which is essential in today’s competitive market. According to a review published in the Applied Sciences, the need for product customization has fueled research aimed at increasing manufacturers’ flexibility to adapt to varying market demands. This has led to advancements in production planning, robotics, and automation, particularly in the semiconductor and electronics industries.

Technological Advancements and Benefits

Technological advancements play a pivotal role in facilitating HMLV manufacturing. The use of collaborative robots (cobots) is one such innovation that enhances flexibility on the shop floor. Cobots can perform a variety of tasks, from machine tending to adaptive assembly, making them ideal for HMLV environments where tasks vary greatly (NIST). Additionally, microfactories, which are highly automated and compact manufacturing setups, enable companies to produce high-mix, low-volume products efficiently. These setups reduce energy and material usage and require a smaller labor force, making them a cost-effective solution for small-scale manufacturing.

Tanjida Tahmina’s Contribution to HMLV Manufacturing

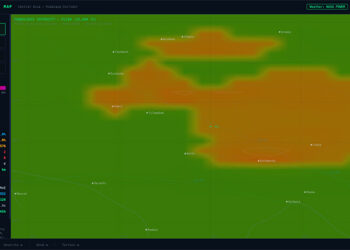

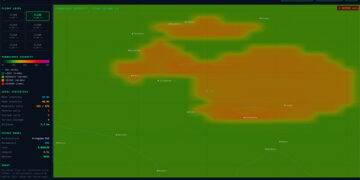

Amidst these advancements, notable contributions have been made by researchers and professionals committed to advancing HMLV manufacturing. One such individual is Tanjida Tahmina, whose impactful research on optimizing HMLV production processes in the defense and aerospace sectors emphasizes the integration of advanced technologies to enhance production efficiency, flexibility, and quality. Her original work has played a key role to demonstrate how smart manufacturing technologies, including additive manufacturing, artificial intelligence, and the Internet of Things (IoT), can leverage real-time data analytics to improve decision-making and operational efficiency in high-mix, low-volume environments. More details on her work can be found here.

Professional Journey and Vision

Tahmina’s professional journey reflects her expertise and dedication to improving manufacturing processes. With over six years of experience leading teams and implementing continuous improvement practices throughout different industries, researchers like her would be at the forefront of the HMLV journey for US. Her research interests span smart manufacturing, Bayesian optimization algorithms, lean manufacturing, and the impact of virtual reality in autonomous driving.

Looking to the future, Tahmina aims to integrate machine learning algorithms and IoT devices to create fully automated and self-optimizing production systems. These innovations promise to make HMLV production more agile, efficient, and responsive to industry demands.

The Future of U.S. Manufacturing

The shift towards high-mix, low-volume manufacturing represents a significant change in how products are made, particularly in the U.S. As industries continue to evolve, the ability to produce a diverse range of products in small quantities will be crucial. This approach not only meets the demand for customization but also supports sustainability by reducing waste and optimizing resource use. As highlighted by McKinsey, industries are recognizing the need to adapt quickly to new market dynamics and technology trends to stay competitive.

In conclusion, the future of U.S. manufacturing lies in embracing high-mix, low-volume production. With innovators like Tanjida Tahmina leading the way, the integration of advanced technologies will continue to drive efficiency and customization, setting new standards for manufacturing excellence.

For more information about Tanjida Tahmina’s research and professional journey, visit her LinkedIn and Google Scholar profile.